Titanium Vs Stainless Steel, What Is The Difference?

Dec 23, 2022

Titanium and stainless steel are two of the most popular materials used in today’s manufacturing industry. They are both solid and durable materials that can be used for various purposes.

But what is the difference between titanium and stainless steel? And which one is better? We will discuss it all in this article.

Titanium

What Is Titanium?

Titanium is a chemical element with the symbol Ti and atomic number 22. It is a lustrous, silver-white, strong metal with low density and a high strength-to-weight ratio. It is highly resistant to seawater, aqua regia, and chlorine corrosion. Titanium was discovered in 1791 and first isolated in 1825 by William Gregor.

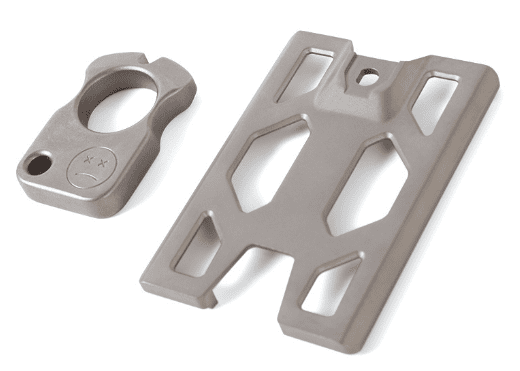

The predominant use of titanium is in the manufacture of aerospace alloys. Other uses: as a pigment; in medical devices and implants; in sporting goods, jewelry, and other consumer products.

How Is Titanium Produced?

Titanium is produced commercially by the Kroll process, which involves the reaction of titanium tetrachloride (TiCl4) with magnesium.

The Kroll process is expensive, and the yield of titanium is low, so various other processes have been developed to produce titanium metal.

One common method is the Hunter process, which involves the reduction of titanium dioxide (TiO2) with aluminum or silicon.

What Are The Properties Of Titanium?

Titanium has a low density and high strength-to-weight ratio. It is highly resistant to seawater, aqua regia, and chlorine corrosion. Titanium is non-magnetic and has very good heat resistance. It is also bio-inert, meaning that it does not react with living tissue.

What Are The Applications Of Titanium?

The predominant use of titanium is in the manufacture of aerospace alloys. Other uses: as a pigment; in medical devices and implants; in sporting goods, jewelry, and other consumer products.

Is Titanium Recyclable?

Yes, titanium is recyclable. However, the recycling process is expensive and not widely used.

Properties Of Titanium

-

Titanium is strong and lightweight.

-

It is corrosion-resistant and does not rust.

-

It is non-magnetic.

-

It has a high melting point.

-

It is available in a variety of grades and finishes.

What Is Titanium Made Of?

Titanium is made of titanium dioxide and iron. Titanium dioxide provides strength and durability, while iron gives the metal its color.

Applications Of Titanium

Titanium has many applications, both industrial and consumer. Some common applications of titanium include:

-

Aircraft parts

-

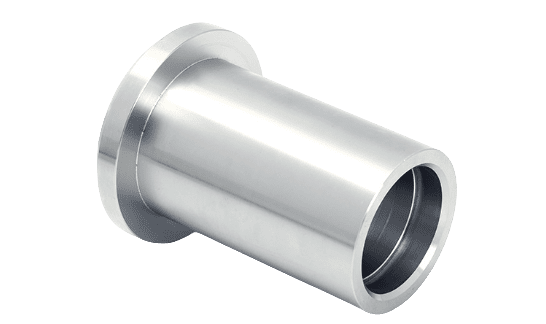

Medical implants

-

Sporting equipment

-

Jewelry and Watches

-

Automotive parts

Summarizing

Titanium is a type of metal known for its high strength-to-weight ratio. It is corrosion-resistant and can withstand high temperatures. Titanium is often used in aerospace and military applications, but it can also be used in other industries such as medical, dental, and sporting goods.

Titanium is often chosen for its lightweight and corrosion resistance. It is also non-magnetic, so it is a good choice for applications where magnetic interference is problematic.

Steel

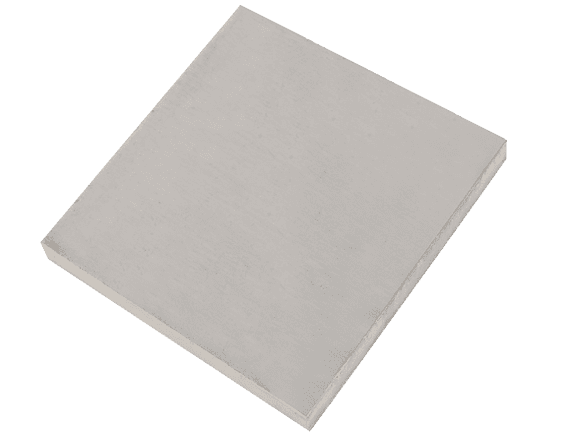

What Is Stainless Steel?

Stainless steel is a type of steel that contains at least 10.5% chromium. The chromium content helps to make the steel stainless, meaning it doesn’t corrode or rust in the presence of water or oxygen.

Stainless steel can be used for various purposes, such as kitchen appliances, cookware, tools, and hardware. It is also used in construction and automotive applications.

Stainless steel is a trendy material in home design. It’s strong, durable, affordable, and easy to clean. It is one of the most durable materials, making it an ideal choice for applications where strength, durability, corrosion resistance, and ease of fabrication are essential.

History Of Stainless Steel

Stainless steel was first invented by Henry Bessemer, a British metallurgist, in 1857. The metal is named after it resists stains or tarnishing, but its composition of iron, chromium, nickel, and carbon means it is resistant to corrosion. In the early 19th century, stainless steel was used to manufacture cutlery and cooking utensils.

Properties Of Stainless Steel

-

Stainless steel is the ideal material for your kitchen and bathroom sink. You can find a wide variety of designs, colors, and sizes. You can find both traditional and contemporary stainless steel sinks in various sizes and finishes.

-

Stainless steel is easy to clean and safe for the environment. It has a high tensile strength, which means it is strong and durable. It is also corrosion-resistant, so you can be sure that your appliances will remain to look great for years to come.

-

Stainless steel is non-porous, so it does not react to acids or alkalis and is very hard. The steel is corrosion-resistant and will not rust. It has high tensile strength (tensile strength is the ability of a material to resist being stretched) and can be used in many applications where the need for high strength is essential. It’s one of the most popular materials for making kitchen knives because of its durability, toughness, and ease of sharpening.

-

Stainless steel is durable and corrosion-resistant. It can be used from kitchenware to jewelry, without maintenance. It’s a highly versatile material, which makes it perfect for industrial and commercial use and household appliances and consumer products. It’s also suitable for food preparation and cooking, as it’s non-reactive to most substances that we commonly find in our kitchens.

-

Stainless steel is resistant to bacteria and viruses. It is easy to clean and maintain. It is solid and durable. It has high heat resistance. It is a good conductor of heat and electricity.

-

Stainless steel is an excellent material for making cookware and other utensils. People often use stainless steel to make items that will stay in their homes for a long time. Most people are pleased to own cookware that is made with stainless steel because of its durability. You can also buy some stainless steel that you can use as jewelry ornaments.

What Is Stainless Steel Made Of?

Stainless steel is made of iron, chromium, and nickel. Carbon steel provides strength and durability, while chromium and nickel help to make the steel stainless.

Applications Of Stainless Steel

Stainless steel is one of the most popular materials globally, and its popularity continues to grow. It is used in various applications, from industrial and commercial use to household appliances and consumer products.

-

Food and beverage containers

-

Kitchen appliances

-

Cutlery

-

Building materials

-

Automotive parts

-

Marine Hardware

Like titanium, stainless steel is often chosen for its corrosion resistance and strength. It is also less expensive than titanium, making it a more affordable choice for some applications.

Summarizing

-

Stainless steel is strong and durable.

-

It does not corrode or rust in the presence of water or oxygen.

-

It can be used for various purposes.

-

It is available in a variety of grades and finishes.

Titanium Vs. Stainless Steel – A Look At Key Differences

Both titanium and stainless steel are types of metal, but there are some key differences between the two.

Here we will explore those differences, explaining each in detail.

Regarding corrosion resistance,titanium and stainless steel are two metals that are often compared. Both metals have their advantages and disadvantages, but which one is more resistant to corrosion?

Stainless steel is the most popular choice for corrosive environmentsbecause it has a high resistance to various forms of corrosion, such as oxidation and pitting. Titanium is also highly resistant to corrosion, but it can be susceptible to environmental factors, such as salt water. In general, stainless steel is better for resisting corrosion in most applications. However, titanium can be a better choice for specific applications where stainless steel may not be as effective.

Ultimately, the choice between titanium and stainless steel depends on the specific application.

Titanium is a much lighter metal than stainless steel.This makes it ideal for use in aircraft and other applications where weight is a critical factor. It also has a higher strength-to-weight ratio than steel, making it ideal for manufacturing high-strength components such as airframe structures and engine casings.

The titanium alloys developed by the aerospace industry have played a vital role in the development of commercial aviation.

Titanium has a higher melting point than stainless steel.For this reason, Titanium is used in the form of a cast blank or ingot, which is then machined into any required shape. The casting blank is heated to near its melting point and then poured into a mold to produce the final shape. Stainless Steel is used for food service equipment, including tabletops, cutting boards, food trays, pans, etc. Stainless steel is also used to manufacture many types of food processing equipment.

Titanium is usually more expensive than stainless steel per unit weight. However, titanium is lighter than stainless steel. So, while titanium may be more expensive on a per-unit-weight basis, it is often the best choice for applications where weight is a concern. For example, airplane manufacturers often use titanium instead of stainless steel to save weight.

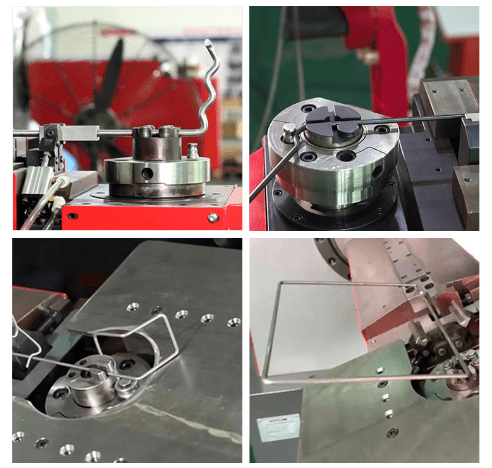

Stainless steel can be bent and shaped more easily than titanium.This is especially true when you want to create a unique piece of jewelry. You can also use it to create a variety of rings, bracelets, necklaces, and earrings. The titanium also has many unique qualities that make it the ideal material for jewelry making. The hardness of titanium makes it one of the best metals for creating jewelry. It is very hard but not brittle like other metals.

Stainless steel is stronger than titanium, making it better suited for heavy-duty applications.Stainless steel’s strength and corrosion resistance make it the ideal choice for equipment that will be used in harsh environments. Titanium is an extremely strong metal, but it’s also very expensive. Stainless steel is a more affordable alternative to titanium, making it the preferred material for many food service applications. The food service industry uses stainless steel pans, bowls, flatware, and utensils.

Titanium is less likely to tarnish or corrode over time than stainless steel.This makes it a better choice for applications exposed to harsh environments, such as outdoor furniture or marine hardware.

Titanium can withstand higher temperatures without melting than stainless steel can.This makes it a better choice for objects exposed to high heat, such as cookware. In addition, titanium is non-toxic, meaning that it poses no health risks if ingested. Stainless steel is not as safe as titanium and can release harmful toxins into food. For these reasons, in some cases, titanium cookware is a better option than stainless steel cookware.

Titanium has a higher resistance to heat than stainless steel does.This is because titanium has a lower coefficient of thermal expansion than stainless steel does. When heated, titanium will expand less than stainless steel, making it less likely to experience warping or buckling. This makes titanium ideal for use in applications exposed to high temperatures, such as exhaust systems or furnace liners.

Stainless steel is easier to weld than titanium.This is because stainless steel has a much higher melting point than titanium. Titanium also has a lower density than stainless steel, making it less likely to form a strong weld. Stainless steel is also less likely to corrode in the presence of oxygen and water, making it a better choice for welding applications.

Both titanium and stainless steel are composed of different elements, which gives them unique properties. Titanium comprises nitrogen, hydrogen, oxygen, carbon, iron, and nickel, while stainless steel contains iron, chromium, and nickel.

Titanium is often seen as a more expensive option than stainless steel.However, this may not always be the case, as there are a variety of different titanium grades available on the market. You typically get what you pay for with stainless steel – the better quality grades will be more expensive. It depends on your needs and budget as to which material is suitable for you.

Titanium produces a brighter spark when struck than stainless steel does.This makes it a better choice for flint and steel fire starters.

Titanium is non-magnetic, while in some cases stainless steel is magnetic.This means that titanium can be used in applications that must be shielded from magnetic fields, such as medical implants or nuclear facilities.

Stainless steel is usually a more affordable option than titanium.This makes it the preferred material for many industrial and commercial applications.

Titanium is biocompatible,meaning that it does not cause any adverse reactions when it comes into contact with human tissue. On the other hand, Stainless steel is not biocompatible in some of its forms.

Titanium is less dense than stainless steel, so it is a good choice for objects that need to be lightweight. Stainless steel is denser than titanium, so it is better suited for applications that require a lot of strength.

Titanium is more corrosion-resistant compared to stainless steel.This means that titanium can be used in marine applications or other environments where exposure to saltwater or other corrosive elements is likely.

In some forms, Titanium has a higher tensile strength than stainless steel does. This means that it can withstand more stress before breaking. Titanium is also less brittle than stainless steel, meaning that it will not shatter when subjected to impact forces.

Stainless steel has a higher resistance to wear and tear than titanium. This makes it a better choice for applications that require a lot of durabilities, such as construction or manufacturing.

Titanium is a good choice for use in dental implants, as it is biocompatible and does not corrode in the presence of saliva. Stainless steel should not be used in dental implants, as it may corrode and cause adverse reactions in the mouth.

Titanium is non-reactive, while stainless steel is reactive.This means that titanium will not release harmful toxins when used in cookware, while stainless steel can release harmful toxins into food. For these reasons, in some cases, titanium cookware is a better option than stainless steel cookware.

Stainless Steel has a higher thermal conductivity than Titanium.This means that it can dissipate heat more effectively, making it a better choice for applications that require a lot of heat. This is why titanium is often used in applications where low thermal conductivity is desired, such as in cooking utensils. Stainless steel is better at transferring heat, so it would be a better choice for cookware that needs to heat up quickly.

Titanium is a good choice for use in aircraft, as it is both lightweight and corrosion-resistant.Stainless steel is not a good choice for use in aircraft, as it is heavy and does not resist corrosion.

Titanium alloys are often used in medical implants because they are biocompatible and do not cause adverse reactions when in contact with human tissue. Stainless steel alloys should not be used in medical implants, as they can cause harmful toxins to leach into the body.

Titanium is a good choice for use in jewelry, as it is strong, lightweight, and non-reactive. In some cases, Stainless steel is not a good choice for use in jewelry, as it is weak and reactive.

Titanium can be difficult to weld, while stainless steel can be easily welded. This means that titanium may require more expertise to weld properly, while anyone with basic welding skills can weld stainless steel.

Titanium is less electrically conductive than stainless steel. Titanium is less electrically conductive than stainless steel. Also, titanium is not a good conductor of heat. So, if you are looking for good material for conducting electricity and heat, stainless steel would be a better choice. Although titanium is much lighter than stainless steel, titanium would be the better option if weight is a concern.

Stainless steel is easier to shape into complex designs than titanium is. It is also less brittle to withstand more wear and tear.

Summarizing

-

Titanium emits less radiation than stainless steel does.

-

Stainless steel is less affected by acids than titanium is.

-

Titanium is less likely to rust than stainless steel.

-

Titanium has a higher resistance to wear and tear than stainless steel does.

-

Titanium is less likely to deform under pressure than stainless steel.

-

Stainless steel can be machined more easily than titanium can be.

In general, titanium is better than stainless steel for most applications. It is more robust, lighter, corrosion-resistant, and has a higher thermal conductivity than stainless steel. Stainless steel is a good choice for applications that require durability or resistance to wear and tear, but titanium is a better option in most cases.

Which Material Is Better?

There is no definitive answer when comparing titanium and stainless steel. Both materials have unique properties that make them suitable for different applications. Stainless steel is stronger and more durable than titanium, ideal for heavy-duty applications.

On the other hand, titanium is lighter and corrosion-resistant, making it a better choice for applications that require a high strength-to-weight ratio. Ultimately, the choice between titanium and stainless steel depends on the application’s specific needs.

The Future Of Stainless Steel

The stainless steel market is expected to grow in the upcoming years This growth is attributed to the increasing demand for stainless steel in the construction and automotive industries. The Asia-Pacific region is expected to be the fastest-growing market for stainless steel during this period, followed by the Middle East and Africa.

The Future Of Titanium

The titanium market size is expected to grow due to its increasing use. This growth is attributed to the increasing demand for titanium in the aerospace and medical industries. The Asia-Pacific region is expected to be the fastest-growing market for titanium during this period, followed by North America.

FAQs

Does Titanium Corrode?

No, titanium does not corrode easily.

Does Stainless Steel Rust?

Yes, stainless steel can rust in harsh conditions.

Can Titanium be Machined?

Yes, titanium can be machined. But it is not as easy to work with.

Can Stainless Steel Be Welded?

Yes, stainless steel can be welded. It is a more common choice for cookware because it is easy to weld.

Can Titanium be Tempered

Yes, titanium can be tempered. It has a higher tensile strength than stainless steel.

Is Stainless Steel A Good Conductor of Electricity and Heat?

Yes, stainless steel is a good conductor of electricity and heat. This is why it is often used in cookware. Titanium is not a good conductor of heat, so stainless steel would be a better choice for cookware that needs to heat up quickly.

What Are Some Applications Where Titanium Would Be A Better Choice Than Stainless Steel?

Titanium is often used in medical implants and other applications where welding is not feasible.

Conclusion

Titanium and stainless steel are two very different metals with unique properties. When deciding which metal to use for a particular application, it is essential to carefully consider all the pros and cons of both options. Titanium is a better choice than stainless steel for most applications. Titanium is stronger, lighter, corrosion-resistant, and has a higher thermal conductivity than stainless steel. Stainless steel is a good choice for applications that require durability or resistance to wear and tear, but titanium is a better option in most cases.