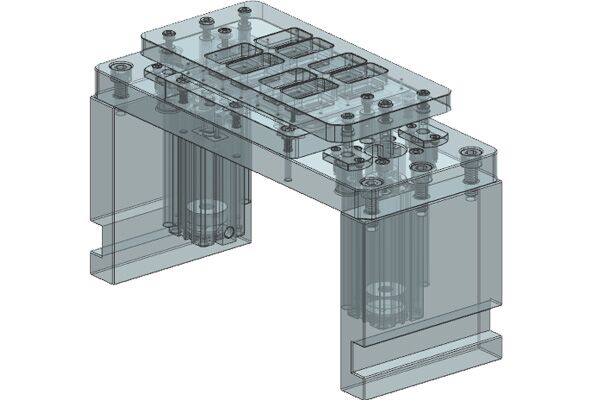

Fixtures & Jigs Machining

We don’t just manufacture parts, components and finished products, but also fixtures and Jigs machining for manufacturing companies. Learn more about these services below.

-

Checking fixtures

Checking fixtures

-

Welding fixtures

Welding fixtures

-

Inspection gauges/fixtures

Inspection gauges/fixtures

-

Assembly fixtures

Assembly fixtures

-

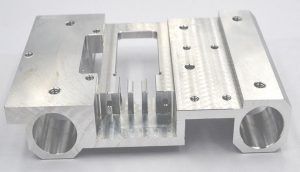

CNC machining fixtures

CNC machining fixtures