Precision machining

From the complex shape machining with high difficulty to the composite machining of several parts, it can provide the precise parts with high integration of CAD / CAM and "technology" accumulated for many years.

For the specific construction method proposal of the final product, all matters can be discussed.

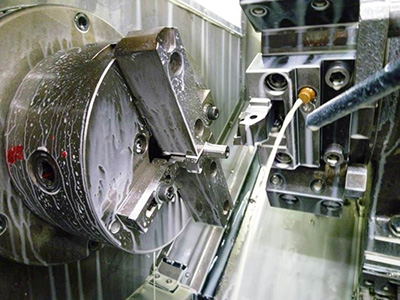

Cutting process

Led by aluminum, stainless steel, nickel series high temperature, corrosion-resistant steel, titanium, metal and other extensive metal materials processing experience. In particular, nickel heat-resistant, corrosion-resistant steel, titanium and so on, have been highly evaluated in the precision machining to maximize the performance of difficult to machine materials.

manufacturing process

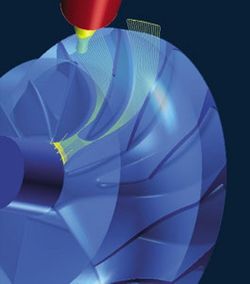

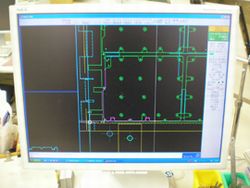

CAD/CAM

CAD data can be supported in 2 and 3 dimensions

From drawing data to CAD / CAM, supporting installation and mechanical input, the network is realized, which greatly shortens the delivery time from ordering to machining. CATIA V5, VERICUT has been imported.

Precision machining

Including 9 high-performance simulation equipment, 25 simulation equipment operate 24 hours

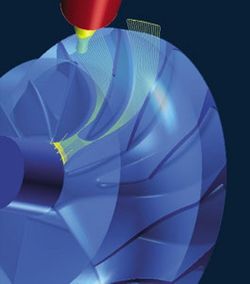

- Simultaneous 5-axis machining:Nesting processing, hose processing

Nested processing

It can be processed with unparalleled simplicity and reliability when challenging the shape of deep cavity, vertical wall with height difference, undercut and curved surface.

Hose processing

The program time is reduced by more than 90%, and the processing time is advanced by 50%. The automatic interference check and interference avoidance function ensures the reliability of the process to the maximum extent.

- ・Universal microtome:Good at small batch, multi variety and high difficulty parts processing, with high quality and stability.

- ・General lathe:They are good at medium quantity and variety processing which need advanced processing technology.

- ・CNC lathe:In the processing of SUS, titanium, molybdenum and other raw materials, we have rich experience and many achievements.

Burr removal

We have skilled workers,

Stable processing of high quality parts

Technology can't rely on mechanical equipment alone. Everyone has many years of experience and superb technology. Through the careful attention of skilled technology, even if it is expanded to 10-20 times, there will be no obstacles to complete the product.

inspect

It has 4 3D measuring instruments. Data can be added

There are hundreds of strict inspection items for each of the aircraft parts and aerospace related parts. If not all of them pass, they are not allowed to be delivered. In addition, it is precisely because of strict inspection items that we can obtain reliable performance. Based on CATIA V5 data, it can be measured through metrology V5.