Mastering ISO 2768-mK: Your Ultimate Guide to General Tolerance Standards

ISO 2768-mK is a widely used standard in engineering and manufacturing industries that defines the general tolerances for linear and angular dimensions without individual tolerance indications. It provides a set of standard tolerances that

The Basics of Injection Molding – All You Need to Know

Injection molding, also known as injection molding, is a prevalent manufacturing technique utilized in industries such as aerospace, automotive, medical, and consumer products. This article provides answers to frequently asked questions abo

Annealing: The Heat Treatment Process for Stronger and More Ductile Materials

Annealing is a heat treatment process that alters the microstructure of a material and thereby changes its mechanical properties. It is often used to improve the materials strength and hardness or to make it more malleable and easier to wor

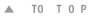

GD&T: The Basics of Geometric Dimensioning and Tolerancing

I. Introduction to GDT Definition of GDT Geometric Dimensioning and Tolerancing, or GDT, is a system of symbols and techniques used to accurately communicate engineering and manufacturing tolerances on drawings and designs. It is a critical

What's The “J” In UNJ Screw Threads?

UNJ, UNJC, UNJF and UNJEF threads are almost identical to UN, UNC, UNF, and UNEF threads except that the external J thread has a much larger root radius than the standard UN threads and inspection must be performed on this element. The Spec

Overview of Carbon Steel: Types, Pros, And Cons

What is Carbon Steel? Carbon steel contains between 0.05 and 2.10% carbon by weight. The American Iron and Steel Institute (AISI) defines carbon steel as follows: There is no minimum content stated chromium, cobalt, molybdenum, nickel, niob

Titanium Vs Stainless Steel, What Is The Difference?

Titanium and stainless steel are two of the most popular materials used in today’s manufacturing industry. They are both solid and durable materials that can be used for various purposes.

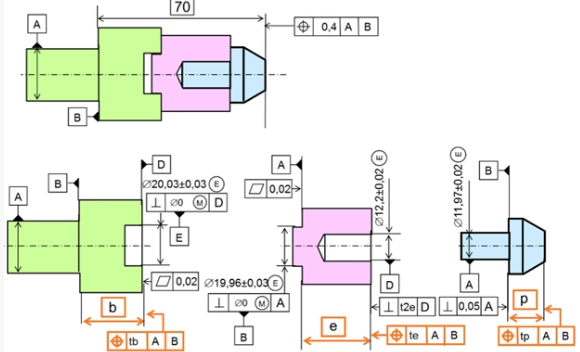

Anodized Aluminum:Process,Benefits,Design Tips

Anodizing is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. The process is called anodizing because the part to be treated forms the anode electrode of an electro