Surface Finishing Services

Various Kind of Options Available Production Level Surface Finishing For Both Metal and Plastic Parts

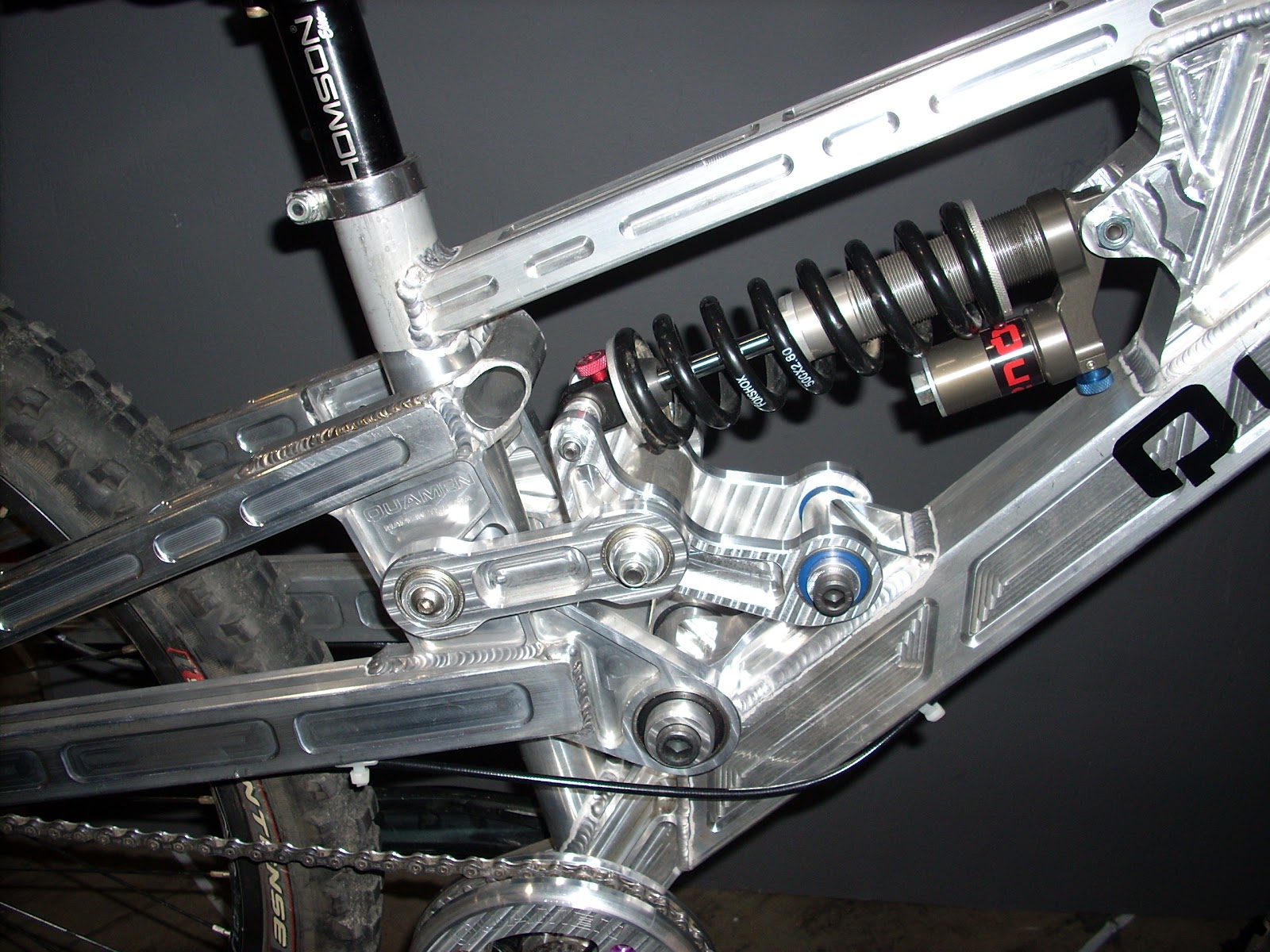

Surface Finishing

Surface finishing refers to different processes used to alter the surface of a manufactured product to give it a distinct or desired look and feel. Different techniques are used to improve the appearance, adherence, solderability, resistance to corrosion, hardness, conductivity and many other characteristics of industrial components.

Seanc offers a high quality surface finishing service for all components and parts regardless of the machining method used in producing them. We have some skilled experts who only handle finishing assignments so the quality of work done on your products is of exceptional quality. If you desire a perfect finish for your prototypes and other manufactured components get in touch with our customer services team for a quick and accurate quotation.

What you can get from us?

High gloss polishing

Painting

Tinted

Tinted is another option to color plastic prototypes besides painting. It is a good solution for turn signal, tail lamp.

Material suit for tinted: ABS PMMA PC PSAnodized

Chromed & Metallizing

This type of finish is only created protect layer, but also a super look.

Chromed Metalspanzing Chrome Sputtering Color Plating Zinc Plating TinningWhy Choose SEANC For Your Surface Finishing

Comprehensive, all-in-one services

We offer machining solution and surface finishing in a single facility. This helps minimize logistical difficulties, and saves you both time and money

Highest standards of quality

We meet relevant ISO requirements for quality and process control,and our safe, advanced facility is staffed by experienced technicians to ensure the best possible results

Scalable for projects of any size

We offer rapid prototyping for small-batch orders, low-volume production and manufacturing for batches of 100,000+ components, and full-scale manufacturing – no project is too big or too small.

Rapid turnaround times available

SEANC offers rush service for select projects, such as urgent prototyping jobs. We can build and send your prototype components anywhere in the world in just a few days.

Advanced, specialized equipment

We use only the most advanced CNC equipment. Not only does this ensure you get the best possible results, but our focus on automation and efficiency means you save money

Experienced and skilled engineers

50+ engineers and desingers, the most specialized and highly-skilled. You can trust our staff to handle your project

Our Latest Blog

Sheet Metal Fabrication

-

We are 100% dedicated to your satisfaction at SEANC

We are 100% dedicated to your satisfaction at SEANC

-

Our Parts shipped to allover the world 80+Countries

Our Parts shipped to allover the world 80+Countries

Visit our Facilities in Shenzhen